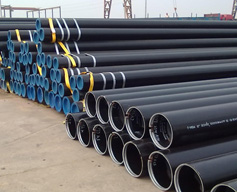

Grade X65 High Yield Pipe and API 5L X65 PSL2 material supplier in India

Toughness and durability are very significant aspects in industries like the oil and gas as well as the petroleum industry. For this reason, carbon steels are frequently utilised to make API 5L X65 Pipe. In addition to being strong, they also have better toughness and hardness qualities than some traditional stainless steel grades. Pipes made of carbon steel API 5L X65 Erw are often regarded as the best option for moving fluids including water, oil, sewage, steam, or gas. Additionally, these API 5L X65 Seamless Pipes made of carbon steel have excellent resistance to shock, vibration, pressure fluctuations, and shock pressure. Although carbon steel grades have a tendency to rust and have little to no corrosion resistant qualities, consumers can request coated or electroplated pipes. These carbon steel pipes often have substantially superior corrosion resistance after surface treatment than if their surface had been left bare. With the application of the proper heat treatment, a layer of zinc might be placed to the outside of the API 5L X65m Welded Pipe.

A standard for materials called NACE MR 0175/ISO 15156 was released by the National Association of Corrosion Engineers, or NACE. The organisation created this US-based standard with the goal of determining whether materials or parts, such as the API 5L X65 Carbon Steel Nace Pipe, are suitable for use as oilfield machinery. Pipes are frequently prone to sulphide stress associated corrosion cracking in situations like hydrogen sulphide or sour environments, such as the oil and gas or petroleum industry.

The International Organization for Standardization's ISO 3183 GR.L450 standard specifies that the Welded steel Pipe should only be used for applications involving pipeline transportation systems in the petroleum and natural gas sectors. The ISO 3183 GR.L450 standard frequently includes the requirements that the technical committee for the ISO recognised as being relevant to the oil and gas sector. For example, the ISO 3183 L450 Pipe PSL 2 has been updated to incorporate standards like the verification detail of crucial processes utilised in the creation of feedstock material, as well as the manufacture of line pipes and product testing, in addition to the inspection details. According to the specification, the API 5L X65 PSL2 pipes also have welded jointers, tightened tolerances for straightness and end squareness, impact test pieces, and placement of hardness testing. We are a provider that offers cut-to-length pipe in every grade, saving you money. The API 5L X65 Pipe provider Rakesh Metals carries pipes in every surface finish.

API 5L X65 PSL2 Carbon Steel Pipe

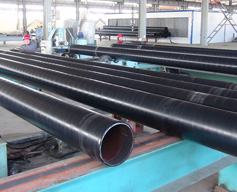

Carbon Steel API 5L Gr. X65 Erw Pipe

API 5L Grade X65 Pipe

Table of contents

- Pressure Rating of API 5L X65 Erw Pipe

- Specification of Api 5l X65 Pipe

- Types of API 5L X65 PSL2 Pipe

- Weight of Api 5l Grade X65 Pipe

- Chemical Composition of Api 5l X65 Pipe

- Sizes of ISO 3183 L450 Pipe

- Types of ISO 3183 L450 Pipeline Coating

- Mechanical Properties of Api 5l X65 PSL2 Pipe

- CS Grade X65 Pipe Surface Finish

- X65 Carbon Steel Pipe Yield Strength

- Equivalent Material of API 5L X65

- Price of API 5L Grade X65 Pipe

Stockist of X65 ERW Pipe and API 5L X65 Seamless Pipe as per EN 10208-1/ EN 10208-2 in 3/4"-24" sizes

Pressure Rating of API 5L X65 Erw Pipe

| Pipe O.D. (in.) |

Wall Thickness of Pipe (inches) | |||||||

|---|---|---|---|---|---|---|---|---|

| .028 | .035 | .049 | .065 | .083 | .095 | .109 | .120 | |

| Working Pressure (psig) | ||||||||

| 1/8 | 7900 | 10100 | ||||||

| 1/4 | 3700 | 4800 | 7000 | 9500 | ||||

| 5/16 | 3700 | 5400 | 7300 | |||||

| 3/8 | 3100 | 4400 | 6100 | |||||

| 1/2 | 2300 | 3200 | 4400 | |||||

| 3/4 | 2200 | 3000 | 4000 | 4600 | ||||

| 1 | 2200 | 2900 | 3400 | 3900 | 4300 | |||

Specification of Api 5l X65 Pipe

| API 5L X65 Seamless Pipe sizes in inch | 1/2 To 60 |

|---|---|

| X65 Carbon Steel SAW Pipe Size in Inch | 16 To 100 |

| API 5L Grade X65 ERW Pipe Size in Inch | 1/2 To 24 |

| X65 Steel LSAW / DSAW Size in Inch | 16 TO 54 Outer Diameter |

| Standard | ISO 3183, API, ASME, ASTM |

| Schedule | Schedule 80S, Schedule 80, Schedule10, Schedule 40, Schedule XXS, Schedule 160, Schedule XS, Schedule 5 Supplier and Manufacturer |

| Pipes Marking | All Pipes are marked as follows: Supplier or Manufacturer’s Name, Standard, Length, Grade, Outer Diameter, Thickness, Heat Number |

| Supplier & Distributors Located in | Ankara, Perth, Dammam, Pimpri Chinchwad, Caracas, Montreal, Tau, New Delhi, Istanbul, Port of Spain, Bengaluru, Indore, Kuwait, India, Howrah, Karachi, Bangalore, Abu Dhabi, Ludhiana, Vadodara, Manama, Kanpur, London, Nagpur, Janeiro, Thiruvananthapuram, Hyderabad, Melbourne, Riyadh, Coimbatore, Baroda, Courbevoie, Ernakulam, Jamshedpur, Calgary, Kolkata, Gimhae si, Tehran, Lagos, Surat, Ranchi, Ludhiana, Khobar, Mexico, Gurgaon, Rajkot, Bogota, Sydney, Muscat, Noida, Mumbai, Chennai, Ahmedabad, Santiago, Ahvaz, Gujarat |

Types of API 5L X65 PSL2 Pipe

API 5L Gr X65 Pipes

API 5L X65 BE Seamless 3LPE Coating Pipe

API 5L Grade X65 Carbon Steel Pipe

API 5L X65 3PE Anti-corrosion insulation pipes

Carbon Steel API 5L X65 Dsaw Pipes

API 5L X65 steel seamless pipes

API 5L Grade X65 Psl2 CS Pipe

API 5L X65 Erw Pipes Lengths X52 API 5L X65 8mm Pipe

API 5L x65 large diameter 24 inch sch 120 pipe

API 5L X65q Pipe

CS API 5L Grade X65 Smls Pipes

API 5L X65 thin wall welded steel pipes

CS 5l Gr X65 thin wall welded galvanized steel pipes

API 5L X65 ERW Welded Steel Pipes

Tuberia API 5L Grade X65 Psl2 Pipes

5l Grade x65 large diameter 24 inch sch 120 pipe

API 5L X65 SCH 40 CS seamless steel pipe

Weight of Api 5l Grade X65 Pipe

| NPS | Outside Diameter | Wall Thickness | Weight | Weight | |||

|---|---|---|---|---|---|---|---|

| in | mm | in | mm | Sched | kg/Mtr | Lb/ft | |

| 1/2″ | 0.840 | 21 | 0.109 | 2.769 | 40 STD | 1.268 | 0.851 |

| 0.147 | 3.734 | 80 STD | 1.621 | 1.088 | |||

| 3/4″ | 1.050 | 27 | 0.113 | 2.870 | 40 STD | 1.684 | 1.131 |

| 0.154 | 3.912 | 80 STD | 2.195 | 1.474 | |||

| 1″ | 1.315 | 33 | 0.133 | 3.378 | 40 STD | 2.501 | 1.679 |

| 0.179 | 4.547 | 80 STD | 3.325 | 2.172 | |||

| 1 1/4″ | 1.660 | 42 | 0.140 | 3.556 | 40 STD | 3.385 | 2.273 |

| 0.191 | 4.851 | 80 STD | 4.464 | 2.997 | |||

| 1 1/2″ | 1.900 | 48 | 0.145 | 3.683 | 40 STD | 4.048 | 2.718 |

| 0.200 | 5.080 | 80 STD | 5.409 | 3.361 | |||

| 2″ | 2.375 | 60 | 0.154 | 3.912 | 40 STD | 5.441 | 3.653 |

| 0.218 | 5.537 | 80 STD | 7.480 | 5.022 | |||

| 2 1/2″ | 2.875 | 73 | 0.203 | 5.516 | 40 STD | 8.629 | 5.793 |

| 0.276 | 7.010 | 80 STD | 11.411 | 7.661 | |||

| 3″ | 3.500 | 89 | 0.216 | 5.486 | 40 STD | 11.284 | 7.576 |

| 0.300 | 7.620 | 80 STD | 15.272 | 10.253 | |||

| 4″ | 4.500 | 114 | 0.237 | 6.020 | 16.073 | 10.790 | |

| 0.337 | 8.560 | 22.318 | 14.983 | ||||

| 6″ | 6.625 | 168 | 0.188 | 4.775 | 19.252 | 12.924 | |

| 0.203 | 5.516 | 20.739 | 13.923 | ||||

| 0.219 | 5.563 | 22.318 | 14.983 | ||||

| 0.250 | 6.350 | 25.354 | 17.021 | ||||

| 0.280 | 7.112 | 40 STD | 58.263 | 18.974 | |||

| 0.312 | 7.925 | 31.334 | 21.036 | ||||

| 0.375 | 9.525 | 37.285 | 25.031 | ||||

| 0.432 | 10.973 | 80 XHY | 42.561 | 28.573 | |||

| 0.500 | 12.700 | 48.719 | 32.708 | ||||

| 8″ | 8.625 | 219 | 0.188 | 4.775 | 25.233 | 16.940 | |

| 0.203 | 5.156 | 27.198 | 18.259 | ||||

| 0.219 | 5.563 | 29.286 | 19.661 | ||||

| 0.250 | 6.350 | 20 | 33.308 | 22.361 | |||

| 0.277 | 7.036 | 30 | 36.786 | 24.696 | |||

| 0.322 | 8.179 | 40 | 42.352 | 28.554 | |||

| 0.375 | 9.525 | 49.216 | 33.041 | ||||

| 0.406 | 10.312 | 60 | 53.085 | 35.638 | |||

| 0.500 | 12.700 | 80 XHY | 64.627 | 43.388 | |||

| 10″ | 10.750 | 273 | 0.188 | 4.775 | 31.588 | 21.207 | |

| 0.219 | 5.563 | 36.689 | 24.631 | ||||

| 0.250 | 6.350 | 20 | 41.759 | 28.035 | |||

| 0.307 | 7.798 | 30 | 51.002 | 34.240 | |||

| 0.344 | 8.738 | 56.946 | 38.231 | ||||

| 0.365 | 9.271 | 40 STD | 63.301 | 40.483 | |||

| 0.438 | 11.125 | 71.852 | 48.238 | ||||

| 0.500 | 12.700 | 60 XHY | 81.530 | 54.735 | |||

| 0.594 | 15.088 | 80 | 95.969 | 64.429 | |||

| 12″ | 12.750 | 324 | 0.188 | 4.775 | 37.570 | 25.222 | |

| 0.219 | 5.563 | 43.657 | 29.309 | ||||

| 0.250 | 6.350 | 49.713 | 33.375 | ||||

| 0.281 | 7.137 | 55.739 | 37.420 | ||||

| 0.312 | 7.925 | 61.735 | 41.445 | ||||

| 0.375 | 9.525 | 73.824 | 49.562 | ||||

| 0.406 | 10.312 | 79.727 | 53.525 | ||||

| 0.500 | 12.700 | 97.438 | 65.415 | ||||

| 0.562 | 14.275 | 108.966 | 73.154 | ||||

| 14″ | 14.000 | 356 | 0.188 | 4.775 | 41.308 | 27.732 | |

| 0.219 | 5.563 | 48.012 | 32.233 | ||||

| 0.250 | 6.350 | 20 | 54.685 | 36.713 | |||

| 0.281 | 7.137 | 61.327 | 41.172 | ||||

| 0.312 | 7.925 | 67.939 | 45.611 | ||||

| 0.375 | 9.525 | STD | 81.281 | 54.568 | |||

| 0.438 | 11.125 | 40 | 94.498 | 63.441 | |||

| 0.500 | 12.700 | XHY | 107.381 | 72.090 | |||

| 0.625 | 15.875 | 132.983 | 89.278 | ||||

| 16” | 16.000 | 406 | 0.188 | 4.775 | 47.290 | 21.748 | |

| 0.219 | 5.563 | 54.980 | 36.910 | ||||

| 0.250 | 6.350 | 10 | 62.639 | 42.053 | |||

| 0.281 | 7.137 | 70.268 | 47.174 | ||||

| 0.312 | 7.925 | 20 | 77.866 | 52.275 | |||

| 0.344 | 8.738 | 85.677 | 57.519 | ||||

| 0.375 | 9.525 |

30 STD |

93.213 | 62.578 | |||

| 0.438 | 11.125 | 108.433 | 72.797 | ||||

| 0.500 | 12.700 |

40 XHY |

123.289 | 82.770 | |||

| 18″ | 18.000 | 457 | 0.219 | 5.563 | 61.948 | 41.588 | |

| 0.250 | 6.350 | 70.593 | 47.393 | ||||

| 0.281 | 7.137 | 79.208 | 53.176 | ||||

| 0.312 | 7.925 | 20 | 87.792 | 58.939 | |||

| 0.375 | 9.525 | STD | 105.144 | 70.588 | |||

| 0.438 | 11.125 | 30 | 122.369 | 82.152 | |||

| 0.500 | 12.700 | XHY | 139.198 | 93.450 | |||

| 0.562 | 14.275 | 40 | 155.904 | 104.666 | |||

| 0.625 | 15.875 | 172.754 | 115.978 | ||||

| 20″ | 20.000 | 508 | 0.250 | 6.350 | 78.547 | 52.733 | |

| 0.282 | 7.163 | 88.458 | 59.386 | ||||

| 0.312 | 7.925 | 97.719 | 65.604 | ||||

| 0.375 | 9.525 | 20 STD | 117.075 | 78.598 | |||

| 0.438 | 11.125 | 136.305 | 91.508 | ||||

| 0.500 | 12.700 | 30 XHY | 155.106 | 104.130 | |||

| 0.594 | 15.088 | 40 | 183.378 | 123.110 | |||

| 0.625 | 15.875 | 192.640 | 129.328 | ||||

| 0.688 | 17.475 | 211.368 | 141.901 | ||||

| 24″ | 24.000 | 610 | 0.250 | 6.350 | 94.456 | 63.413 | |

| 0.281 | 7.137 | 106.029 | 71.183 | ||||

| 0.312 | 7.925 | 117.573 | 18.932 | ||||

| 0.375 | 9.525 | 20 STD | 140.938 | 64.618 | |||

| 0.438 | 11.125 | 164.176 | 110.219 | ||||

| 0.500 | 12.700 | XHY | 186.923 | 125.490 | |||

| 0.625 | 15.875 | 232.410 | 156.028 | ||||

| 0.688 | 17.475 | 40 | 255.148 | 171.293 | |||

| 0.750 | 19.050 | 277.401 | 186.233 | ||||

| 30″ | 30.000 | 762 | 0.250 | 6.350 | 118.318 | 79.433 | |

| 0.281 | 7.137 | 132.851 | 89.189 | ||||

| 0.312 | 7.925 | 10 | 147.353 | 98.925 | |||

| 0.375 | 9.525 | STD | 176.731 | 118.648 | |||

| 0.438 | 11.125 | 205.983 | 138.286 | ||||

| 0.500 | 12.700 | 20 XHY | 234.647 | 157.530 | |||

| 0.625 | 15.875 | 30 | 292.066 | 196.078 | |||

| 0.688 | 17.475 | 320.817 | 215.380 | ||||

| 0.750 | 19.050 | 348.988 | 234.293 | ||||

| 36″ | 36.000 | 914 | 0.250 | 6.350 | 142.180 | 95.453 | |

| 0.281 | 7.137 | 159.672 | 107.196 | ||||

| 0.312 | 7.925 | 10 | 177.133 | 118.918 | |||

| 0.375 | 9.525 | STD | 215.525 | 142.678 | |||

| 0.438 | 11.125 | 247.790 | 166.353 | ||||

| 0.500 | 12.700 | 20 XHY | 282.372 | 198.570 | |||

| 0.625 | 15.875 | 351.723 | 236.128 | ||||

|

0.688 |

17.475 | 386.487 | 259.467 | ||||

|

0.750 |

19.050 | 420.576 | 282.353 | ||||

| 42″ | 42.000 | 1067 | 0.312 | 7.925 | 206.914 | 138.911 | |

| 0.375 | 9.525 | STD | 248.319 | 166.708 | |||

| 0.500 | 12.700 | XHY | 33.097 | 221.610 | |||

| 0.750 | 19.050 | 492.163 | 330.413 | ||||

| 48″ | 48.000 | 1219 | 0.375 | 9.525 | STD | 284.112 | 190.738 |

| 0.438 | 11.125 | 331.404 | 222.487 | ||||

| 0.500 | 12.700 | XHY | 377.822 | 253.650 | |||

| 0.750 | 19.050 | 563.750 | 378.473 | ||||

| 0.875 | 22.225 | 655.969 | 440.383 | ||||

get API 5L X65 PSL2 Pipe Chemical Composition and API 5L X65 Tubes Wall Thickness

Chemical Composition of Api 5l X65 Pipe

| Grade | Carbon | Manganese | Phosphorus | Sulfur | Vanadium | Niobium | titanium | |

|---|---|---|---|---|---|---|---|---|

| Minimum | Maximum | |||||||

| B | 0.28 | 1.2 | – | 0.03 | 0.03 | c.d | c,d | d |

| X65 | 0.28 | 1.4 | – | 0.03 | 0.03 | f | f | f |

API 5L X65Q PSL 2

| Grade | Carbon | Manganese | Phosphorus | Sulfur | Vanadium | Niobium | titanium | Other | |

|---|---|---|---|---|---|---|---|---|---|

| X65Q | 0.18 | 0.45 | 1.7 | 0.025 | 0.015 | g | g | g | h,l |

Sizes of ISO 3183 L450 Pipe

| TYPE | OD | Thickness |

|---|---|---|

| SEAMLESS | 1/4 - 36 inch | 1.25 - 50mm |

| ERW | 1/8 - 24 inch | Max 26.5mm |

| LSAW | 219 - 3120mm | 3 - 25mm |

| SSAW | 16 - 64 inch | 3 - 25mm |

API 5L X65 Gr B Pipe Material Stock

| API 5L X65 Gr B Seamless Pipes | 5L X65 Grade B Welded Pipes |

| X65 Steel Erw Pipes | 5L X65 Line Pipes |

| ISO 3183 L450 Pipeline | Grade X65 Pipes Line |

| X65 PSL2 Sour Service Pipes | X65 PSL2 LSAW Pipes |

| X65 Carbon Steel Nace Pipeline | X65 Carbon Steel PE Coated Pipes |

| 5L X65 Gr B Gas Pipeline | 5L Grade X65 PTFE Lined Pipes |

| X65 Steel Water Pipeline | X65 Steel Epoxy Coated Pipes |

| ISO 3183 L450 Air Pipes | ISO 3183 L450 Spiral Welded Pipes |

| 5L X65 Gr B Oil Linepipes | X65 Steel Bare Pipes |

| ISO 3183 L450 Powder Coated Pipes | API 5L Grade X65 Pipes Sleeve material |

| Steel X65 3LPP Coating Pipes | Grade X65 3LPE Coated Pipes |

| 5L X65 Grade B Drill Pipes | API 5L X65 Cement Lined Pipes |

Types of ISO 3183 L450 Pipeline Coating

Mechanical Properties of Api 5l X65 PSL2 Pipe

| Grade | Yield Stress Mpa | Tensile Stress Mpa | Elongation |

|---|---|---|---|

| X65 | 450 | 535 | c |

| Grade | Yield Stress Mpa | Tensile Stress Mpa | Raito | Elongation | ||

|---|---|---|---|---|---|---|

| Minimum | Maximum | Minimum | Maximum | Maximum | Minimum | |

| BN | 245 | 450 | 415 | 655 | 0.93 | f |

| BQ | ||||||

| X65Q | 450 | 600 | 535 | 760 | 0.93 | f |

Your need for API 5L X65 PSL 1, X65q, X65m and X65 Dsaw Pipe of standard length and diameter ends here, We provide the best quality range of API 5L X65 material

CS Grade X65 Pipe Surface Finish

Surface Finishes: Bare, Tape Wrap, FBE, 3LPP, Mill Varnish, Galv, Concrete Coating, FBE Dual, Coal Tar, Oiled, 3LPE,.

End Finishes: Square Cut, Beveled, Coupled, Threaded

X65 Carbon Steel Pipe Yield Strength

| Grade | Yield Stress | Tensile Stress | Yield to Tensile | Elongation |

|---|---|---|---|---|

| Minimum | Minimum | Ratio | % | |

| API 5L X65 Pipe | 65 | 77 | 0.93 | 18 |

Equivalent Material of API 5L X65

| Gr | PSL1 | L450 or x65 |

| Gr | PSL2 | L450Q or X65Q L450M or X65M |

Pioneer Supplier Of API 5L X65 Sour Service and API 5L X65 PSL 1 SAW Pipe and Tube at best price

Price of API 5L Grade X65 Pipe

| Description | Price Per Ton in INR | Price Per Ton in USA $ | Price Per Ton in UAE Dirham |

|---|---|---|---|

| API 5L x65 Spiral Galvanized Weld Steel Pipe | INR 43888.23 | USA $ 600 | AED 2203.86 |

| API 5L X65 SCH80-SCH160 ERW with Black varnished carbon Steel Pipe | INR 32770.82 | USA $ 450 | AED 1652.94 |

| API 5L X65 seamless carbon steel pipe 1/2" to 60" | INR 36573.53 | USA $ 500 | AED 1836.55 |

| API 5l X65 20 inch LSAW Weld Carbon Steel Pipe | INR 29129.62 | USA $ 400 | AED 1469.28 |

| API 5l gr x65 psl 2 carbon steel seamless pipe | INR 61900.44 | USA $ 850 | AED 3122.22 |